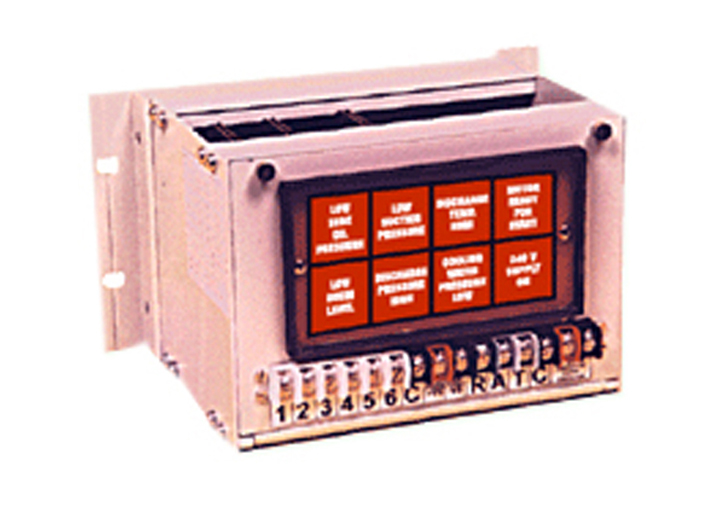

Dynatek offers cost effective solution for Compressor Control systems. The latest technology is put into use to provide maximum features and to make control panel compact. This system offers Annunciation and controlling with audio/visual signal and potential free O/P contacts. Control Panel consists three detachable cards (CPU, Relay & Power) assembled in international EURO standard enclosure to have easy access for site maintenance. The compactness and light weight of control panel makes it ideal to put into Flameproof / Weatherproof enclosures when it is used for LPG / AIR Compressor or used in hazardous area.

Microcontroller based Control system continuously monitors the connected inputs. When fault condition occurs in any one of the connected inputs, unit indicates the fault by flashing respective window and energies Hooter Relay & trips the compressor motor. After acknowledge the fault Hooter will be off but unit is not allow to start the Compressor as soon the fault is retified and Reset it allow to start compressor. All the Inputs have site selection facility for “NO” (make to alarm) and “NC” (break to alarm). User can connect a Hooter through relay for Audio alarm. Facility to connect external “Test, Accept & Reset” push buttons is available on front terminals. Dual rate flashing is provided for differentiating the first & subsequent faults. In built Digital four step Timer is provided for "LUB OIL PRESSURE".

| Window Indication | : | Bright Red LED display. |

| Fault Inputs | : | Potential free contact "NO" or "NC" Micro switch or Aux. Contact of contactor |

| Flash Rates | : | For first fault 300 flashes/min. & subsequent fault 60 flashes/min. |

| Output Relay Contact Rating for Hooter | : | 3A / 230 VAC, 5A / 24VDC It is advisable to cascade relay for heavy load. |

| External Test, Accept and Reset | : | By "NO" push buttons |

| Operating Supply | : | 110/230 VAC , 50 Hz + 15% |

| Legend | : | Positive and Negative photo film |

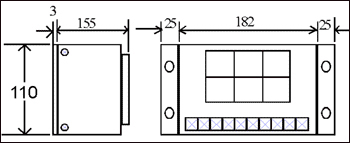

| Mechanical Details | : |  |