Any manufacturing process or equipment needs close monitoring, it is effectively done by employing Annunciation system. The system provides Audio and Visual indication of faults. DYNATEK make AB/ABM series is one of the most advanced, highly reliable and compact micro-controller based alarm annunciation system. The system offers annunciation with signaling and Auxiliary (open collector) output. Annunciation inputs are connected to potential free contacts. When fault condition occurs in any one of the connected inputs, annunciator indicates the fault by flashing respective window and energies Hooter Relay. The AB / ABM series inputs have site selection facility for “NO” (make to alarm) and “NC” (break to alarm). User can connect a Hooter through relay for Audio alarm. Facility to connect external “Test, Accept & Reset” push buttons is available on the back side terminals. Dual rate flashing is provided for differentiating the first & subsequent faults

Accepting inputs from PLC or SCADA.

Now a days in many Automation projects Potential free contacts are sensed by PLC or log in SCADA. But some times for same inputs Annunciation is required at site, in that case lot of hard wiring is required . But this hard wiring can be eliminated by using DYNATEK Annunciator which accepts inputs from PLC by only twisted two wires on RS485 bus(Modbus Protocol).

Up to 32 annunciator units can be surveyed & controlled by software package (SCADA with Modbus I/O Driver). Faults at each Alarm annunciator are logged by the software in a computer file, which can be used later for analysis. The connection from the PC to the units is via. 2 wire RS-485 Bus, using standard RS-485 twisted pair shielded communication cable.

| Model | ABM04 | ABM06 | AB08 | AB10 | AB12 | AB14 | AB16 |

|---|---|---|---|---|---|---|---|

| Fault Input Points | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| Power Consumption - VA | 1.6 | 1.8 | 7.7 | 8.5 | 9.1 | 9.8 | 10.5 |

| Weight - gm. | 330 | 330 | 710 | 710 | 710 | 710 | 710 |

| Window Indication | - | Bright Red LED display. |

|---|---|---|

| Fault Inputs | - | Potential free contact "NO" or "NC" Micro switch or Aux. Contact of contactor |

| Flash Rates | - | For first fault 300 flashes/min. & subsequent fault 60 flashes/min. |

| Output Relay Contact Rating for Hooter | - | 250mA / 230VAC, 1A / 24 VDC It is advisable to connect additional relay for heavy load |

| Additional Open Collector o/p for mimic or remote display | - | 100mA Sinking mode |

| External Test, Accept and Reset | - | By "NO" push buttons |

| Operating Supply | - | 12/24/48 V AC/DC 110/230 VAC , 50 Hz + 15% (Using additional rectifier card) |

| Leagend | - | Positive and Negative photo film |

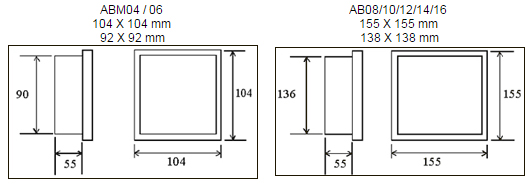

| Mechanical Details Bezel Size Cut out Size |

- |  |